Best quality 6w Bubble Corduroy Fabric - 100% cotton 21W corduroy fabric 40*40 77*177 for garments, kids garment, shirt, bags and hats, coat, pants – Xiang Kuan

Best quality 6w Bubble Corduroy Fabric - 100% cotton 21W corduroy fabric 40*40 77*177 for garments, kids garment, shirt, bags and hats, coat, pants – Xiang Kuan Detail:

| Art No. | MDF18911Z |

| Composition | 100%Cotton |

| Yarn Count | 40*40 |

| Density | 77*177 |

| Full Width | 57/58″ |

| Weave | 21W Corduroy |

| Weight | 140 g/㎡ |

| Fabric Characteristics | High strength, stiff and smooth, texture ,fashion, environmentally friendly |

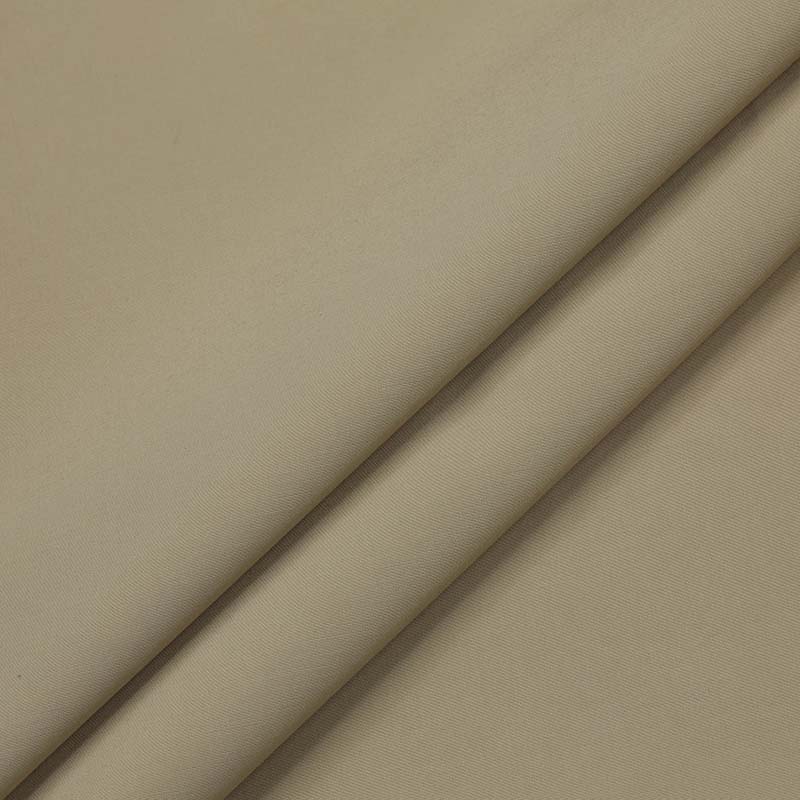

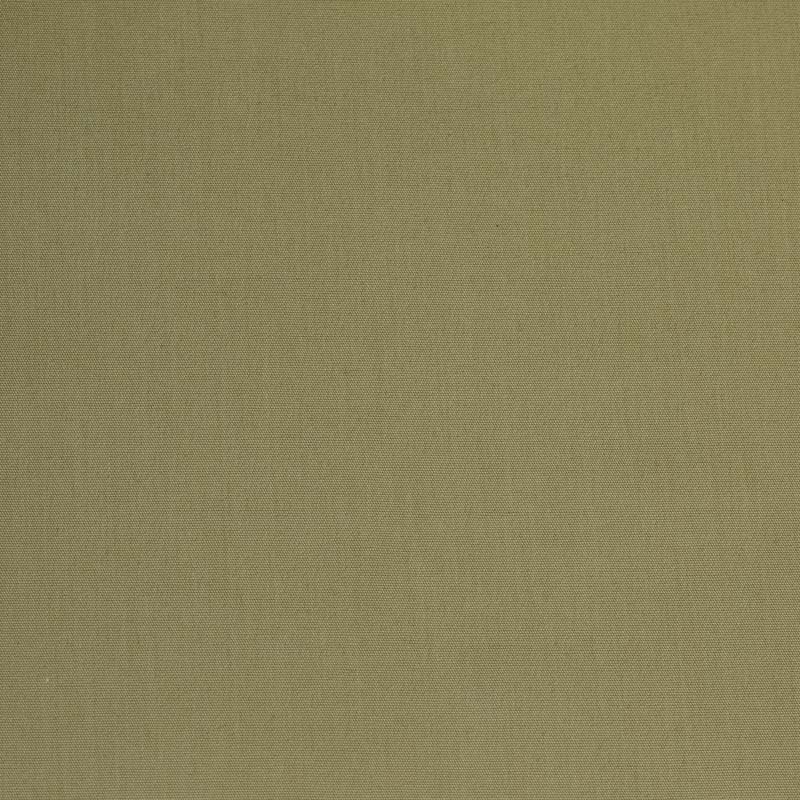

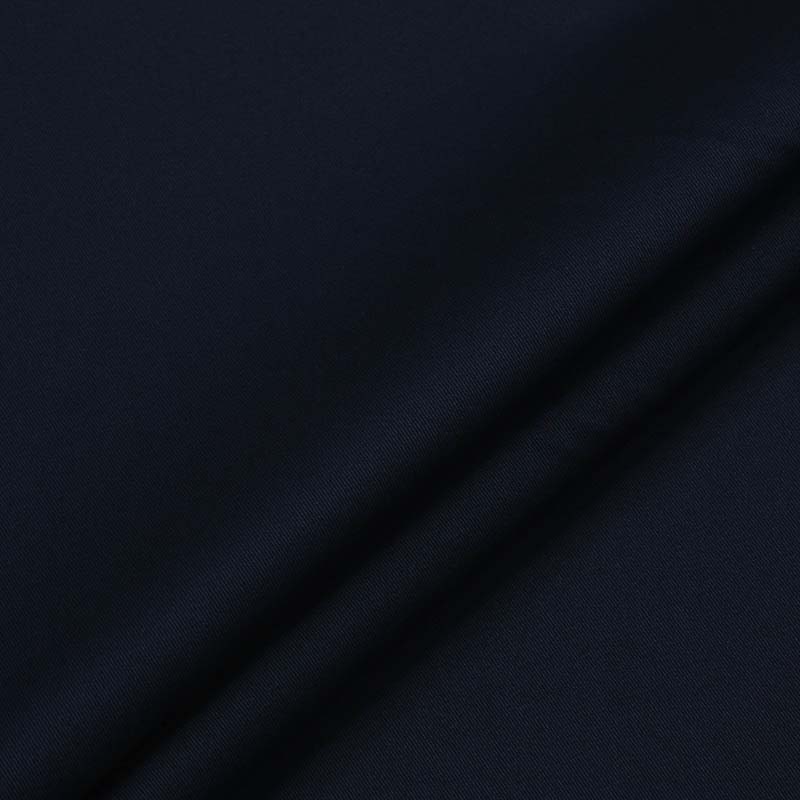

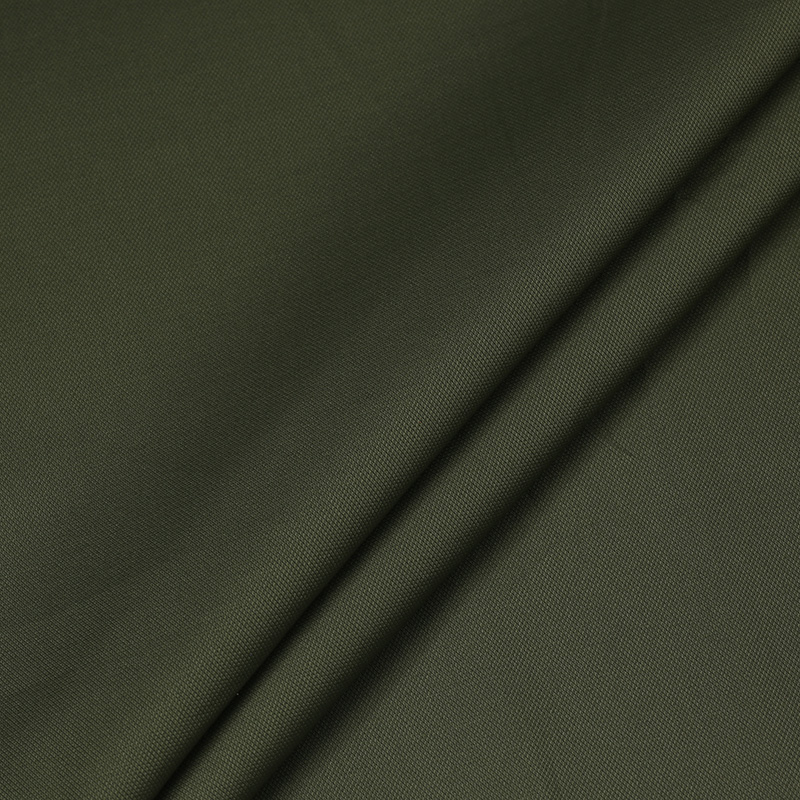

| Available Color | Khaki,Dark Pink, etc. |

| Finish | Regular |

| Width Instruction | Edge-to-edge |

| Density Instruction | Finished Fabric Density |

| Delivery Port | Any port in China |

| Sample Swatches | Available |

| Packing | Rolls, fabrics length less than 30 yards are not acceptable. |

| Min order quantity | 5000 meter per color,5000 meter per order |

| Production Time | 25-30days |

| Supply Ability | 300,000 meters per month |

| End Use | Coat, Pants, Outdoor Garments, etc. |

| Payment Terms | T/T in advance, LC at sight. |

| Shipment Terms | FOB, CRF and CIF, etc. |

Fabric Inspection:

This fabric can meet GB/T standard, ISO standard, JIS standard, US standard. All the fabrics will be 100 percent inspected before shipment according to American four point system standard.

How is corduroy fabric made?

The production processes used to make corduroy vary depending on the types of materials used. Cotton and wool are derived from natural plant and animal sources respectively, for instance, and synthetic fibers like polyester and rayon are produced in factories.

Once textile manufacturers have acquired one or more types of yarn, however, corduroy fabric production follows a universal set of steps:

1. Weaving

Most types of corduroy fabric feature plain weaves, which consist of weft threads that alternate over and under warp threads. It’s also possible to make corduroy using a twill weave, but this approach is less common. Once the primary weave is complete, textile manufacturers add a “pile thread,” which will be cut to form corduroy’s characteristic ridges.

2. Glueing

Glue is applied to the back of the woven fabric to ensure that the pile yarn does not pull through during the cutting process. Textile producers remove this glue later in production.

3. Cutting of pile yarn

Textile manufacturers then use an industrial cutter to sever the pile yarn. This yarn is then brushed and singed to produce soft, uniform ridges.

4. Dyeing

To produce a unique, irregular pattern, textile manufacturers can pigment-dye completed corduroy fabric. The pattern that this dyeing process produces becomes more accentuated as it is washed, providing one of the most visually appealing facets of corduroy fabric.

Product detail pictures:

Related Product Guide:

Gaining purchaser gratification is our firm's intention eternally. We will make wonderful endeavours to build new and top-quality merchandise, satisfy your exclusive needs and provide you with pre-sale, on-sale and after-sale products and services for Best quality 6w Bubble Corduroy Fabric - 100% cotton 21W corduroy fabric 40*40 77*177 for garments, kids garment, shirt, bags and hats, coat, pants – Xiang Kuan , The product will supply to all over the world, such as: Vancouver, Porto, Paraguay, We strive for excellence, constant improvement and innovation, is committed to make us the "customer trust" and the "first choice of engineering machinery accessories brand" suppliers. Choose us, sharing a win-win situation!

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!