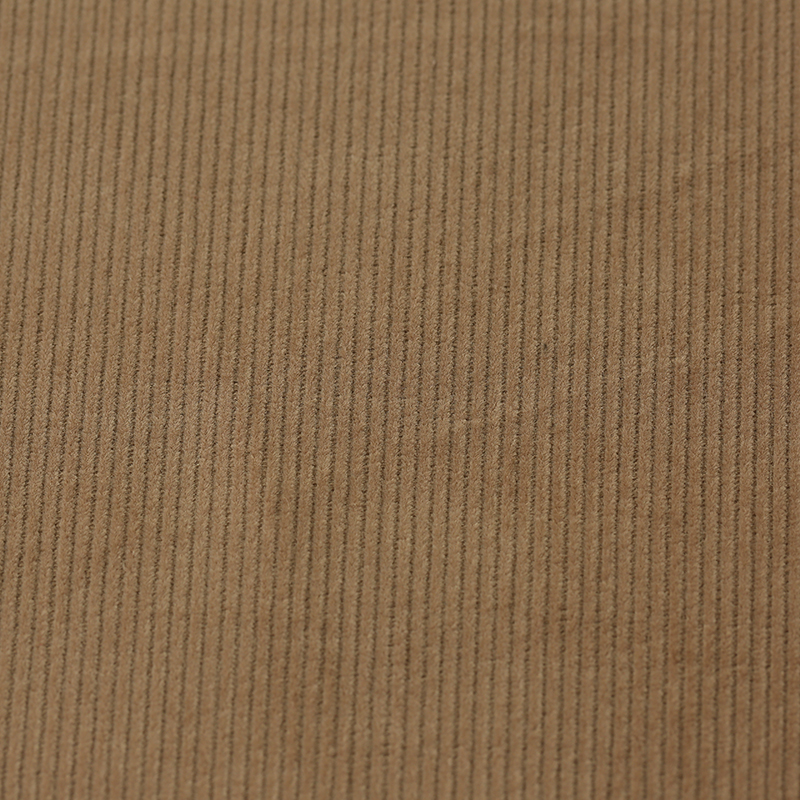

Factory wholesale Beige Corduroy Fabric - 88% cotton 12% Nylon Canvas fire retardant + water repellent fabric 86*48/12+12*12+12 for flame retardant protective clothing – Xiang Kuan

Factory wholesale Beige Corduroy Fabric - 88% cotton 12% Nylon Canvas fire retardant + water repellent fabric 86*48/12+12*12+12 for flame retardant protective clothing – Xiang Kuan Detail:

| Art No. | MEZ1206X |

| Composition | 88% Cotton 12% Nylon |

| Yarn Count | 12+12*12+12 |

| Density | 86*48 |

| Full Width | 58/59″ |

| Weave | Canvas |

| Weight | 285g/㎡ |

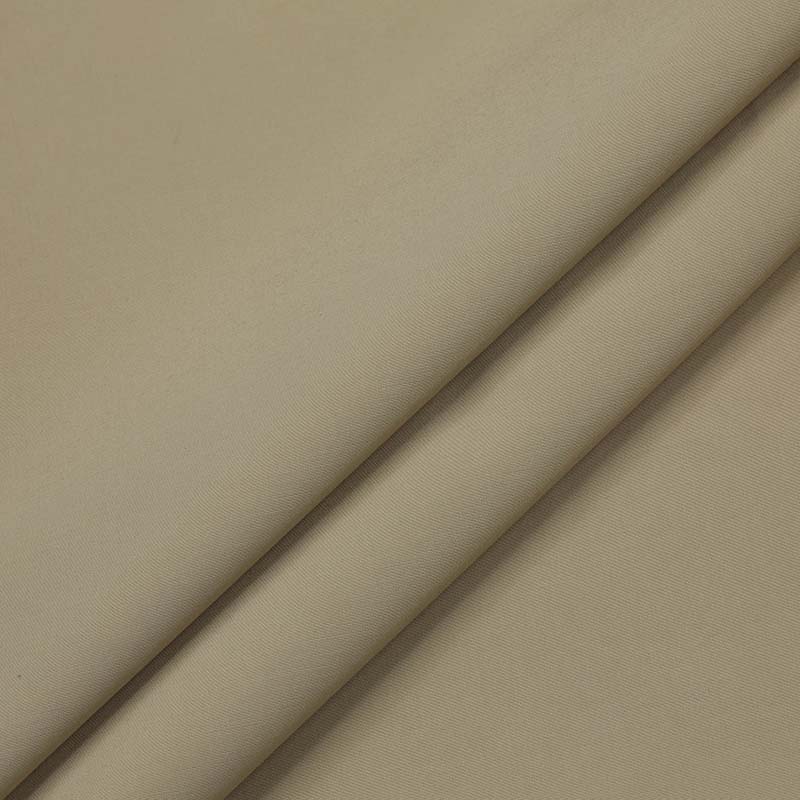

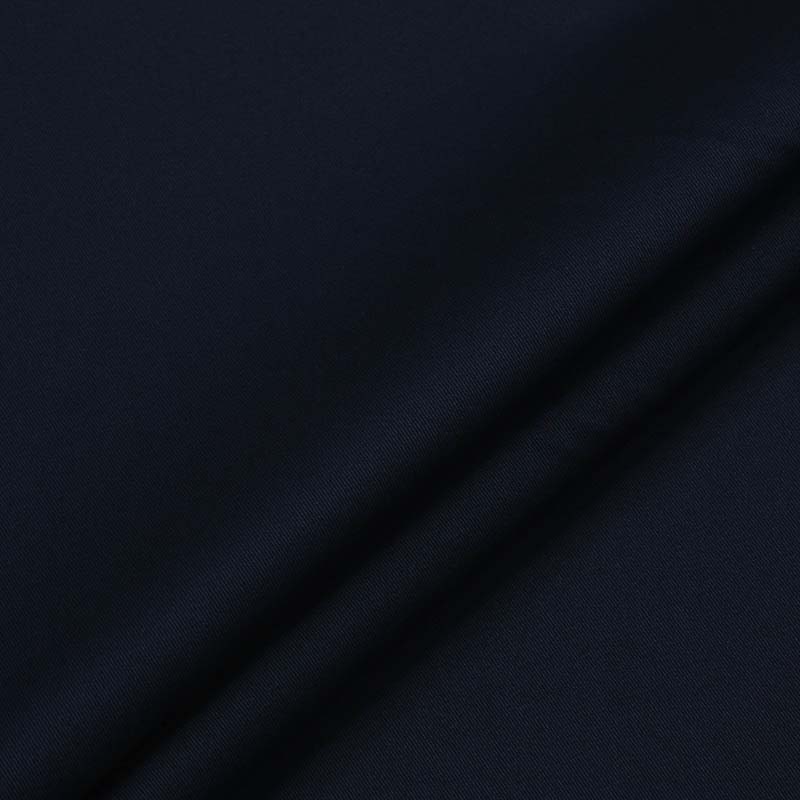

| Available Color | Navy etc. |

| Finish | Flame Retardant, Fire Retardant, water repellent |

| Width Instruction | Edge-to-edge |

| Density Instruction | Finished Fabric Density |

| Delivery Port | Any port in China |

| Sample Swatches | Available |

| Packing | Rolls, fabrics length less than 30 yards are not acceptable. |

| Min order quantity | 5000 meter per color,5000 meter per order |

| Production Time | 30-35days |

| Supply Ability | 200,000 meters per month |

| End Use | Flame retardant protective clothing for metallurgy, machinery, forestry, fire protection and other industries |

Payment Terms: T/T in advance, LC at sight.

Shipment Terms: FOB, CRF and CIF, etc.

Fabric Inspection: This fabric can meet GB/T standard, ISO standard, JIS standard, US standard. All the fabrics will be 100 percent inspected before shipment according to American four point system standard.

| Fabric Composition | 88% Cotton 12% Nylon | |||

| Weight | 285g/㎡ | |||

| Shrinkage | EN 25077-1994 | Warp | ±3% | |

| EN ISO6330-2001 | Weft | ±3% | ||

| Color fastness to washing(After 5 washes) | EN ISO 105 C06-1997 | 4 | ||

| Color fastness to dry rubbing | EN ISO 105 X12 | 4 | ||

| Color fastness to wet rubbing | EN ISO 105 X12 | 3 | ||

| Tensile strength | ISO 13934-1-1999 | Warp(N) | 1287 | |

| Weft(N) | 634 | |||

| Tear strength | ISO 13937-2000 | Warp(N) | 61.2 | |

| Weft(N) | 56 | |||

| Flame retardant performance index | EN11611;EN11612;EN14116 | |||

| Water repellent | AATCC 22 Before Wash | Grade 5 | ||

| AATCC 22 After 5Washes | Grade 3 | |||

The end use of fire retardant fabric

Fire retardant fabrics are used in a variety of applications like industrial work wear, uniforms for fire fighters, air force pilots, tent and parachute fabric, professional motor racing apparel etc to protect the wearer against fires, and electrical arcs etc. They are mostly used in interior materials like curtains, in hotels, hospitals and theaters. Materials like Twaron are used in fabrics to withstand high temperature in industry like fire fighting. Materials like aluminum hydroxide are commonly used as fire retardant as it gives three way protection. It breaks down to give off water vapor, and further absorbs much heat, thereby cooling the material and the residue of alumina and forms a protective layer.

Flame retardancy of a fabric depends on the number of times; the fabric is dry cleaned, and the environmental conditions in which the fabric is used. The fire retardant properties of a finished fabric are normally tested by using addon, tensile strength, LOI-value, and vertical flame test determinations.

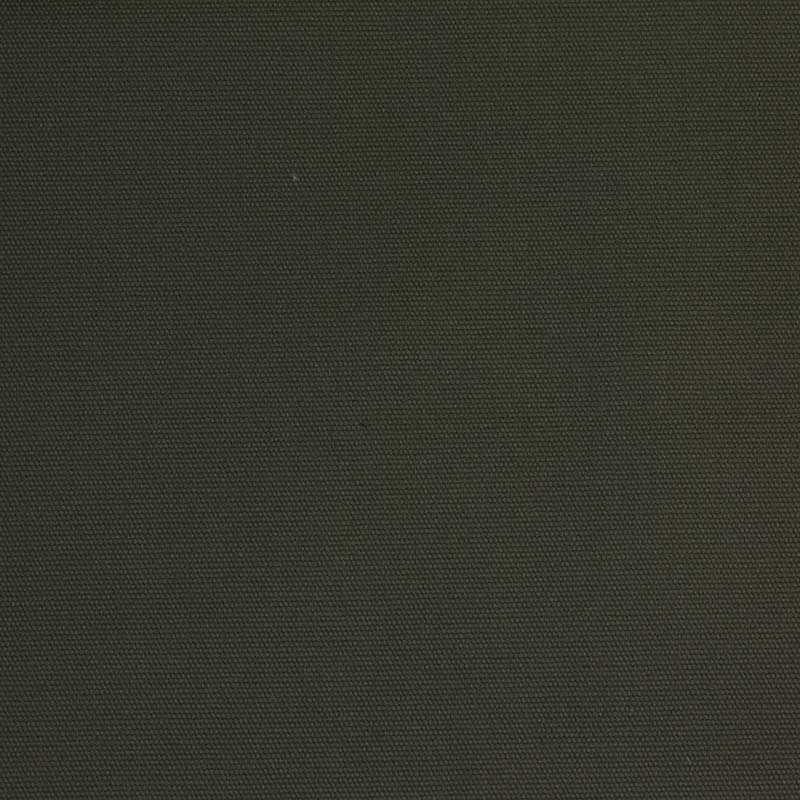

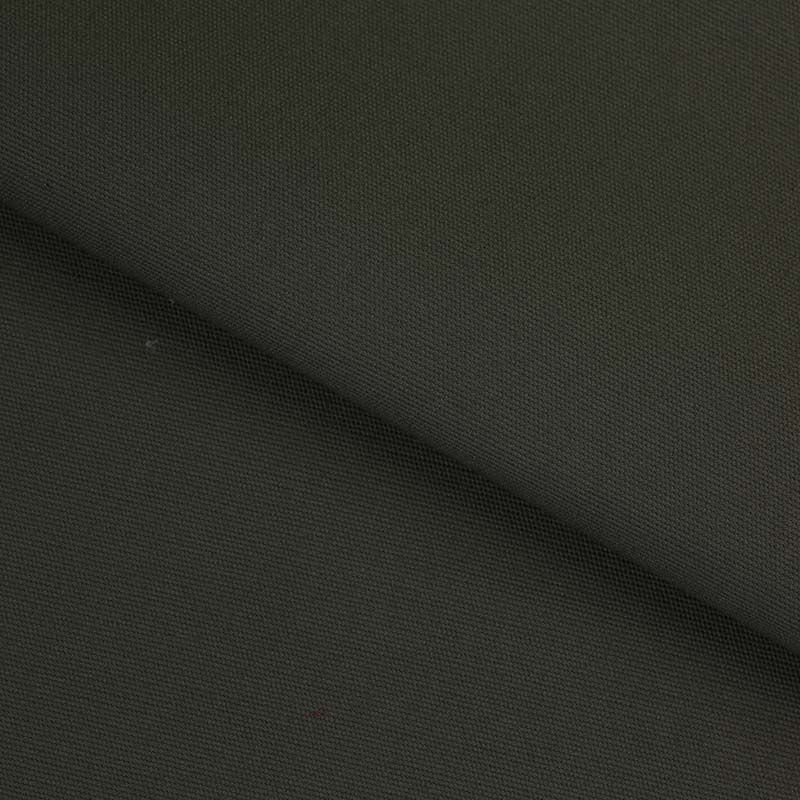

Product detail pictures:

Related Product Guide:

We now have our own gross sales team, style and design workforce, technical crew, QC workforce and package group. We now have strict quality manage procedures for each system. Also, all of our workers are experienced in printing industry for Factory wholesale Beige Corduroy Fabric - 88% cotton 12% Nylon Canvas fire retardant + water repellent fabric 86*48/12+12*12+12 for flame retardant protective clothing – Xiang Kuan , The product will supply to all over the world, such as: Bogota, United States, Surabaya, We are proud to supply our products to every auto fan all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!