PTA doesn’t smell good? Many giants successively “out of the circle”, what happened?

Burst! Ineos, Rakuten, Mitsubishi exit PTA business!

Mitsubishi Chemical: On December 22, Mitsubishi Chemical successively announced a number of news, including the announcement of the planned transfer of 80% of the shares of its Indonesian subsidiary and the appointment of senior personnel such as a new CEO.

At an executive meeting held on the 22nd, Mitsubishi Chemical Group decided to transfer 80% of its shares in Indonesia’s Mitsubishi Chemical Corporation (PTMitsubishi Chemical lndonesia) to PT Lintas Citra Pratama. The latter operates a pure terephthalic acid (PTA) business.

MCCI has been manufacturing and selling Ptas in Indonesia since its inception in 1991. While the PTA market and business in Indonesia are stable and strong, the Group continues to consider the direction of the business while advancing its portfolio management with a focus on market growth, competitiveness and sustainability in line with its “Build the Future” business approach.

A subsidiary of PT Lintas CitraPratama plans to commercialize paraxylene, the main raw material of PTA, in Southeast Asia.

Previously, chemical new materials have reported that international giants including Ineos and Lotte Chemical have closed/withdrawn from PTA projects.

Lotte Chemical announced: completely quit PTA business

Lotte Chemical announced that it plans to sell its 75.01% stake in Lotte Chemical Pakistan Limited (LCPL) and completely exit the refined terephthalic acid (PTA) business. The divestment is part of Lotte Chemical’s medium-term strategy to strengthen its high value-added specialty materials business.

Located in Port Qasim, Karachi, LCPL produces 500,000 tons of PTA per year. The company sold the business to Lucky Core Industries(LCI), a Pakistani chemical company, for 19.2 billion won (about 1.06 billion yuan) (Lotte Chemical bought LCPL for 14.7 billion won in 2009). LCI mainly produces PTA derivative polyester, producing 122,000 tons of polyester polymer and 135,000 tons of polyester fiber per year in Lahore, while 225,000 tons of soda ash per year in Heura.

Lotte Chemical said that the proceeds from the sale of the PTA business will be used to develop the existing market for high value-added products such as polyethylene, polypropylene and polyethylene terephthalate, and expand the specialty chemicals business and enter the environmental materials business.

In July 2020, Lotte Chemical stopped producing PTA at its 600,000-ton/year plant in Ulsan, South Korea, and converted it to a facility for the production of fine isophanic acid (PIA), which currently has a PIA capacity of 520,000 tons/year.

Ineos: Announced the closure of a PTA unit

On 29 November, Ineos announced that it intends to close the smaller and older of the two PTA (refined terephthalic acid) units at its PX and PTA integrated production facility at its plant in Herr, Antwerp, Belgium.

The unit has been out of production since 2022 and a review of its long-term prospects has been under way for some time.

Ineos said in its public press release that the main reasons for the closure of the plant are: the increase in energy, raw material and labor costs makes European production less competitive with the export of new PTA and derivative capacity in Asia; And the group wants to focus more on high-end new materials.

Crazy production of raw materials, downstream “0″ demand?

Looking at the domestic PTA market, as of now, the average annual PTA price in 2023 has declined compared with 2022.

Although the recent Red Sea crisis combined with the domestic local closure caused by the cold wave weather, PTA oscillated upward; However, the end of the end of the textile orders are not good, downstream spinning, weaving enterprises lack confidence in the future market, in the context of their own inventory increase and financial pressure on the high price of raw materials resistance is strong, resulting in polyester varieties spot pull up difficult, resulting in polyester varieties profit level decline significantly.

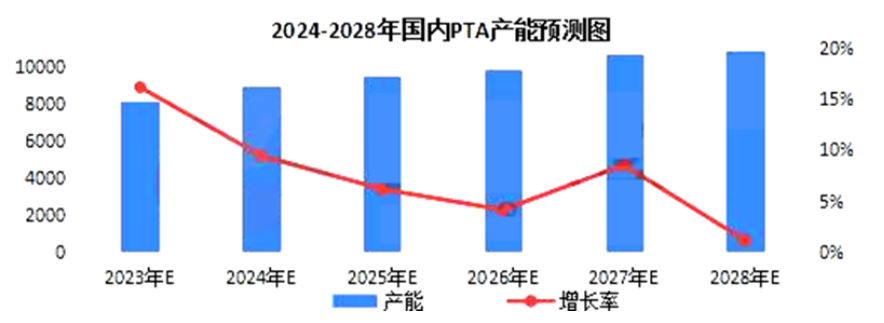

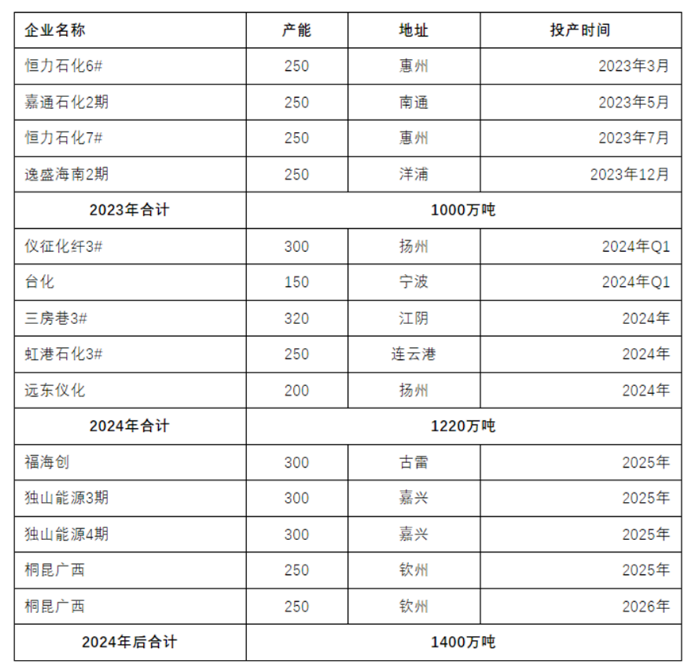

In addition, with the rapid development of integration projects, the future PTA capacity is still showing an increasing trend. In 2024, domestic PTA is expected to put into production of 12.2 million tons, and PTA capacity growth rate may reach 15%, from the perspective of production capacity, PTA may face greater excess pressure.

In recent years, the domestic PTA industry has experienced a period of excess capacity and reshuffle to capacity, the change in the supply pattern has a greater impact on the market, with the new equipment put into operation, the future domestic PTA industry oversupply situation or more severe.

Elimination speed up! The industry is becoming increasingly competitive

With the production of a series of large PTA devices, the overall capacity of PTA has been very large, and the industry competition has become increasingly fierce.

At present, PTA leading enterprises continue to reduce processing fees, seize market share, eliminate backward production capacity, most of the devices with high processing costs have been eliminated, and in recent years, the newly put into production of PTA devices are more than 2 million tons of advanced devices in large factories, and the average processing cost of the industry has decreased significantly. In the future, the advanced production capacity will increase, and the average processing cost of the internal device of the industry to produce PTA will decrease with the production, and the processing fee will be at a low level for a long time.

Therefore, in the context of oversupply, intensifying industry competition, and shrinking profits, corporate survival is undoubtedly difficult, so it seems that Ineos, Rakuten, Mitsubishi’s choice is also reasonable, whether it is to focus on the main business to divest business, or to break arms to survive, or to prepare for subsequent cross-border and other strategies.

Source: Guangzhou Chemical Trade Center, Network

Post time: Jan-02-2024