On February 20, lululemon partnered with Australian environmental technology startup Samsara Eco to launch the world’s first enzymatically recycled nylon 6,6 product, marking a major milestone in textile-to-textile recycling and lululemon’s work to create a circular ecosystem. lululemon used recycled nylon 6,6 made from Samsara Eco technology to create a sample of its signature Swiftly Tech long-sleeved top, the first time such nylon has been recycled in this way.

Approximately 4 million tons of nylon 6,6 are produced each year, one of the most commonly used plastics in the textile industry and the foundation fiber for lululemon to make many of its best-selling products, such as Align and Wunder Train leggings. Nylon 6,6 is notoriously difficult to recycle and has been widely used in industries such as fashion, automotive and electronics due to its tough and durable properties. Today, recycled nylon is typically made from post-industrial material waste, and there are a limited number of recycled alternatives that meet lululemon’s product performance standards. Samsara Eco’s technology works by using engineered enzymes to break down nylon 6,6 synthetic mixtures to recreate nylon 6,6, which can then be turned back into clothing.

Yogendra Dandapure, Vice President of Raw Materials Innovation at lululemon, said: “lululemon Swiftly’s top samples go beyond materials innovation – they represent the exciting possibilities and impact that can be achieved through collaboration and cross-industry collaboration. This breakthrough marks a turning point not only for sustainable innovation in clothing, but for all industries looking to move to a more circular model. We look forward to continuing to work with Samsara Eco to help roll out this new technology in the months and years ahead.” ”

More than 90 percent of the nylon used in each lululemon Swiftly top sample was produced using Samsara Eco’s enzyme recovery process, and these samples provide the same fit, feel and quality that guests expect from lululemon products. The Swiftly sample also demonstrated the company’s end-to-end loop vision to take lululemon nylon apparel, including lululemon leggings, at the end of the lifecycle stage and combine it with other non-textile materials to create recycled nylon for use in new lululemon products.

Paul Riley, CEO and founder of Samsara Eco, said: “Our partnership with lululemon represents a breakthrough step in addressing the challenge of textile waste and demonstrates the potential to create a fully circular ecosystem for clothing. We started with nylon 6,6, but as we continue to expand our library of plastic eating enzymes, this sets the trajectory of possibilities for recycling across a range of industries. This is a very important moment for the future of sustainable fashion and recycling. ”

As previously reported:

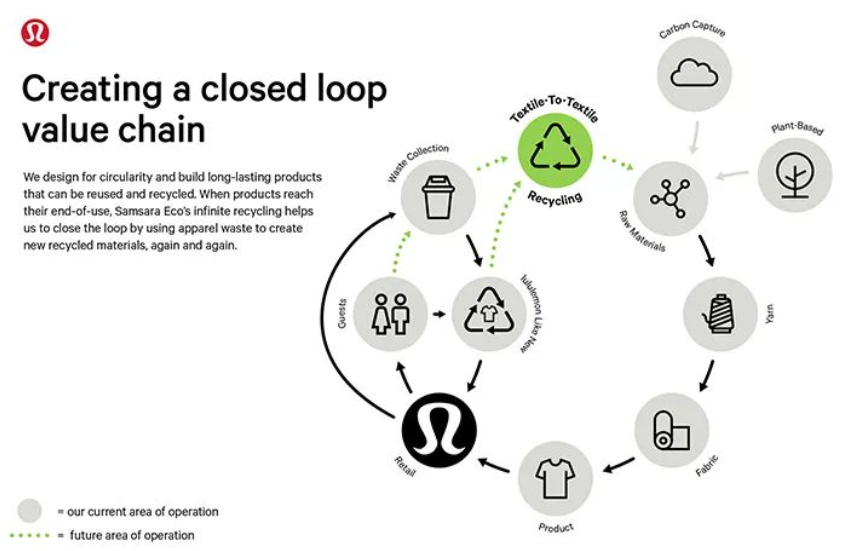

lululemon has announced a multi-year partnership with Australian eco-tech startup Samsara Eco to expand the cycle through textile-to-textile recycling. Through this innovative collaboration, lululemon is working to make unlimited recycled nylon and polyester from its products using this circular process.

This partnership is the latest example of the company’s Be Planet goal and an exciting step towards achieving a circular ecosystem by 2030. Samsara Eco is a leader in unlimited plastic recycling, recycling the high-performance nylon and polyester blends that are at the heart of lululemon products.

“Nylon remains our greatest opportunity to achieve our 2030 sustainable product goals. This partnership demonstrates the possibility of addressing unmet needs through collective innovation.” Yogendra Dandapure, Vice president of raw material Innovation at lululemon, said, “Through Samsara Eco’s patented enzyme processing process, we are advancing the conversion of apparel waste into high-quality nylon and polyester, which will help us realize our end-to-end recycling vision.”

This is lululemon’s first minority investment in a recycling company and Samsara Eco’s first collaboration in the apparel industry. Following a $56 million Series A funding round last year, lululemon’s partnership and investment comes as Samsara Eco prepares to commercialize, bringing unlimited recycling potential to the fashion industry. This is an important milestone in Samsara Eco’s roadmap to recycle 1.5 million tons of plastic per year by 2030. Together, the two companies will manufacture new recycled nylon and polyester from apparel waste, bringing low-impact alternatives to important materials for the high-performance apparel industry.

Ted Dagnese, chief Supply Chain Officer at lululemon, said: “Our partnership with Samsara Eco is a fundamental step towards a circular ecosystem. We are driving innovation across the value chain and we are excited about what this means for the global performance apparel industry and our journey to zero energy.”

Recycling will play a big role in the future of retail and clothing. lululemon is advancing its value chain, including

Sustainable Materials: Last April, lululemon launched its first products made from plant-based nylon from renewable sources as part of a multi-year partnership with sustainable materials leader Geno.

Customer Experience: Continued strong performance and high engagement in lululemon’s Like New re-commerce program has extended product design life.

Textile-to-textile recycling: Together with Samsara Eco, lululemon is recycling its clothing into new products that use waste to retrofit recycled nylon and polyester.

“We are proud that this partnership is disrupting the apparel industry. Samsara Eco’s ability to recycle mixed textiles, including nylon, indefinitely offers an important solution to the challenge of textile waste. This is unprecedented, and partnering with lululemon is an important milestone that will accelerate the closed-loop journey of textile recycling.” Paul Reilly, CEO and founder of Samsara Eco.

lululemon is committed to making products that are better in every way by setting science-based goals that are the foundation of the climate action goals outlined in the Brand Impact Agenda.

Sources: Chemical fiber headlines, lululemon, NTMT Textile New materials, network

Post time: Mar-05-2024