OEM Customized Military Duck Canvas - 98% cotton 2% Elastane 14W Corduroy fire retardant fabric 51*134/12*16+16+70D for flame retardant protective clothing – Xiang Kuan

OEM Customized Military Duck Canvas - 98% cotton 2% Elastane 14W Corduroy fire retardant fabric 51*134/12*16+16+70D for flame retardant protective clothing – Xiang Kuan Detail:

| Art No. | MDF1205X |

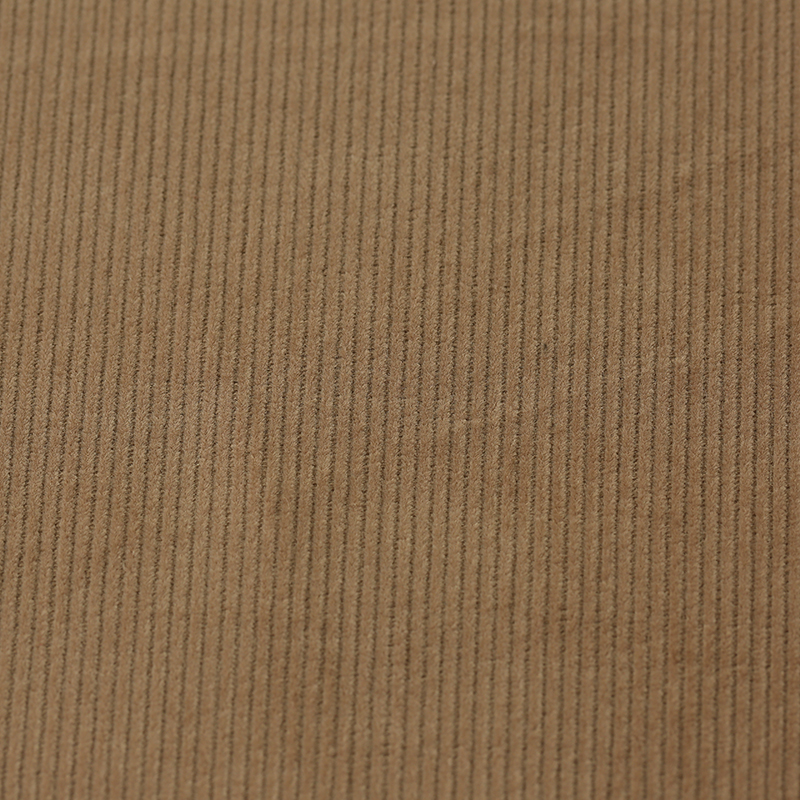

| Composition | 98%Cotton2%Elastane |

| Yarn Count | 12*16+16+70D |

| Density | 51*134 |

| Full Width | 58/59″ |

| Weave | 14W Corduroy |

| Weight | 395g/㎡ |

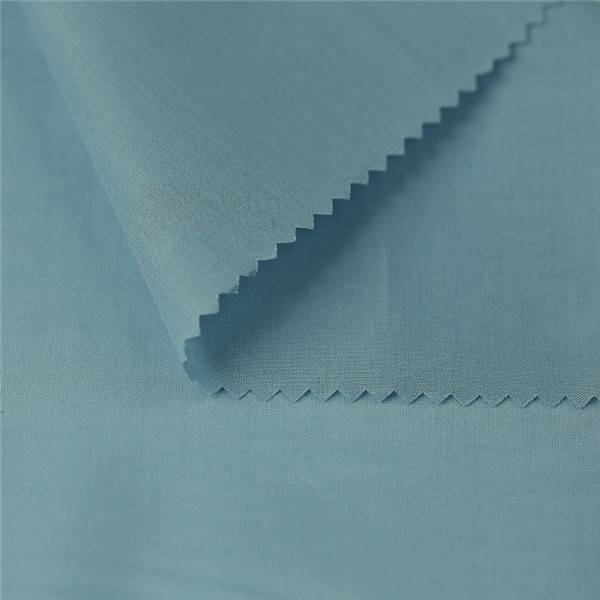

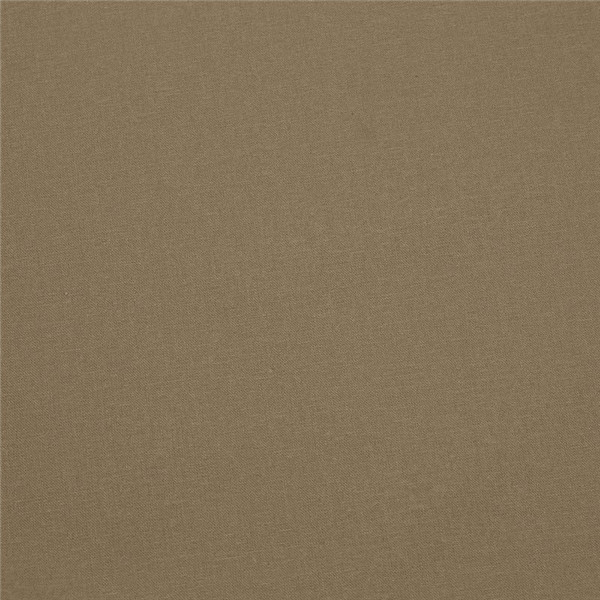

| Available Color | Grey, Khaki etc. |

| Finish | Flame Retardant, Fire Retardant |

| Width Instruction | Edge-to-edge |

| Density Instruction | Finished Fabric Density |

| Delivery Port | Any port in China |

| Sample Swatches | Available |

| Packing: | Rolls, fabrics length less than 30 yards are not acceptable. |

| Min order quantity | 5000 meter per color,5000 meter per order |

| Production Time | 30-35days |

| Supply Ability | 100,000 meters per month |

| End Use | Flame retardant protective clothing for metallurgy, machinery, forestry, fire protection and other industries |

Payment Terms: T/T in advance, LC at sight.

Shipment Terms: FOB, CRF and CIF, etc.

Fabric Inspection: This fabric can meet GB/T standard, ISO standard, JIS standard, US standard. All the fabrics will be 100 percent inspected before shipment according to American four point system standard.

| Fabric Composition | 98%Cotton2% Elastane | ||

| Weight | 395g/㎡ | ||

| Shrinkage | EN 25077-1994 | Warp | ±3% |

| EN ISO6330-2001 | Weft | ±5% | |

| Color fastness to washing(After 5 washes) | EN ISO 105 C06-1997 | 3-4 | |

| Color fastness to dry rubbing | EN ISO 105 X12 | 3-4 | |

| Color fastness to wet rubbing | EN ISO 105 X12 | 2-3 | |

| Tensile strength | ISO 13934-1-1999 | Warp(N) | 883 |

| Weft(N) | 315 | ||

| Tear strength | ISO 13937-2000 | Warp(N) | 30 |

| Weft(N) | 14 | ||

| Flame retardant performance index | EN11611;EN11612;EN14116 | ||

World-wide market for Fire Retardant Fabrics:

Global demand for fire retardant fabrics is expected to increase by 4.7 percent and the global market is estimated to grow more than 2 million metric tons by the year 2011. Formulation and practice of stringent flammability standards will lead to the increased use of flame retardants by the developing countries. U.S will be a leading producer of these fabrics. Demand for fire retardant fabrics in U.S. is anticipated to have an average annual increase of 3 percent making its market to go beyond 1 billion pounds by the year 2011. Increasing use of flame retardants in consumer products, building materials, wire and insulation jacketing, electronics housings and aerospace products will boost its market demand. Polyolefin and other thermoplastics market will see increasing gain as they are used in flame retardant construction applications.

Performance apparel is one of the fastest growing sectors of the textile industry. The market growth is enhanced by the emergence of new innovations in fabrics and technological updations. Developments in fabric industry have led to the innovation of high-tech protective fabrics. These fabrics possess great tensile strength, cut resistance, and even higher abrasion resistance and durability.

Product detail pictures:

Related Product Guide:

Our target is to consolidate and improve the quality and service of existing products, meanwhile constantly develop new products to meet different customers' demands for OEM Customized Military Duck Canvas - 98% cotton 2% Elastane 14W Corduroy fire retardant fabric 51*134/12*16+16+70D for flame retardant protective clothing – Xiang Kuan , The product will supply to all over the world, such as: Borussia Dortmund, Japan, Bangladesh, Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!