OEM Customized Organic Corduroy Fabric - 100% cotton 3/1 S Twill 108*58/21*21 Chlorine bleach resistance fabric for hospital,work wear – Xiang Kuan

OEM Customized Organic Corduroy Fabric - 100% cotton 3/1 S Twill 108*58/21*21 Chlorine bleach resistance fabric for hospital,work wear – Xiang Kuan Detail:

| Art No. | MBF4169Z |

| Composition | 100%Cotton |

| Yarn Count | 21*21 |

| Density | 108*58 |

| Full Width | 57/58″ |

| Weave | 3/1 S Twill |

| Weight | 1380g/㎡ |

| Finish | Chlorine bleach resistance |

| Fabric Characteristics | comfortable, chlorine bleach resistance, environmental friendly |

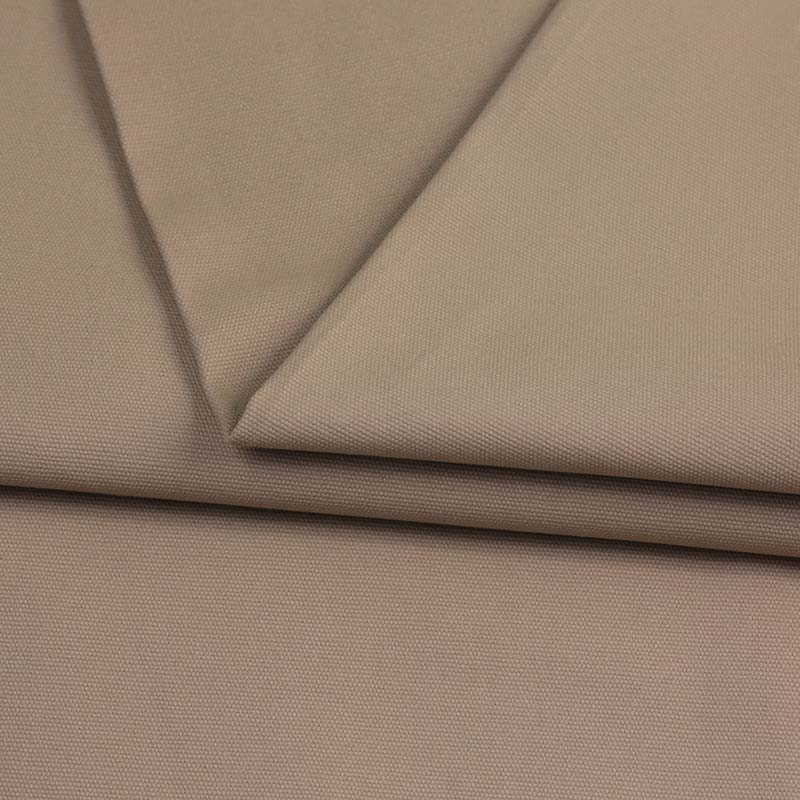

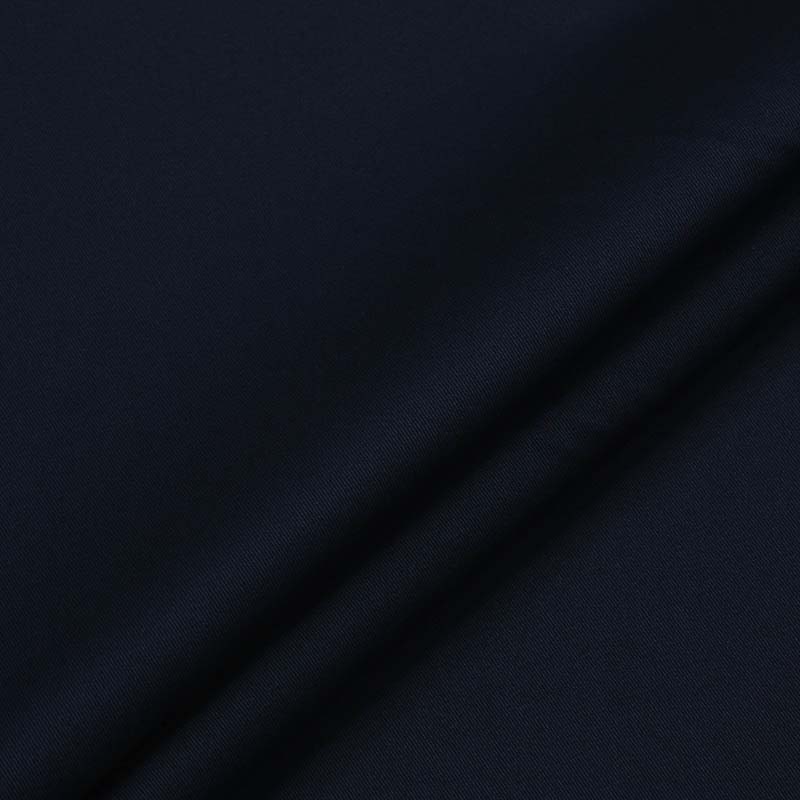

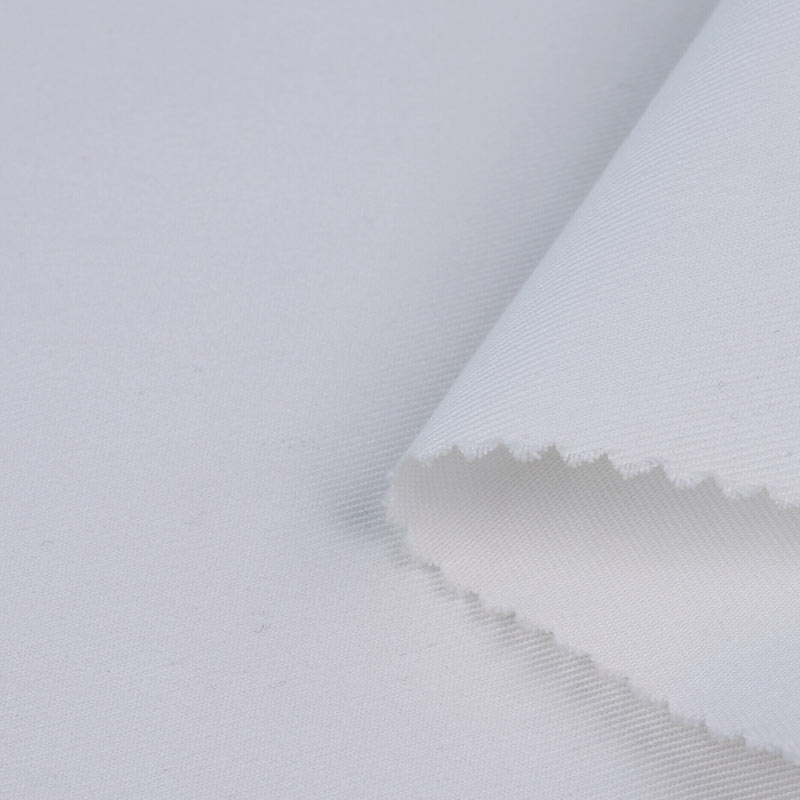

| Available Color | blue,white etc. |

| Width Instruction | Edge-to-edge |

| Density Instruction | Greige Fabric Density |

| Delivery Port | Any port in China |

| Sample Swatches | Available |

| Packing | Rolls, fabrics length less than 30 yards are not acceptable. |

| Min order quantity | 5000 meter per color,5000 meter per order |

| Production Time | 25-30days |

| Supply Ability | 200,000 meters per month |

| End Use | hospital fabric, work wear etc. |

| Payment Terms | T/T in advance, LC at sight. |

| Shipment Terms | FOB, CRF and CIF, etc. |

Fabric Inspection: This fabric can meet GB/T standard, ISO standard, JIS standard, US standard. All the fabrics will be 100 percent inspected before shipment according to American four point system standard.

The processing methods of antibacterial textiles are as follows:

1. Spinning treatment method:

There are two types of spinning methods: blended spinning and composite spinning:

The first is the blended spinning method. The blended spinning method is to mix auxiliaries such as antibacterial agents and dispersants with the fiber matrix resin to produce antibacterial fibers by melt spinning. This method is mainly aimed at some fibers without reactive side groups, such as polyester, polypropylene, etc.; the antibacterial agent not only exists on the surface of the fiber, but also is uniformly dispersed in the fiber, and the antibacterial effect is relatively long-lasting. Antibacterial fabrics prepared by this method are mainly used in medical hygiene and clothing as well as industrial decorative fabrics.

Next is the composite spinning method. The composite spinning method uses the fibers containing antibacterial components and other fibers or fibers without antibacterial components to composite spinning to make side-by-side, core-sheath, mosaic, and hollow multi-core structures. Antibacterial fiber.

2. Post finishing method:

In the conventional production process of the printing and dyeing factory, the antibacterial finishing process is completed by dipping or padding the antibacterial solution and then drying.

The characteristics of post-finishing are: no additional equipment is required, and the process and operation are simple; after processing, the color, whiteness, shade, strength and other indicators of the textile will not be changed.

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for OEM Customized Organic Corduroy Fabric - 100% cotton 3/1 S Twill 108*58/21*21 Chlorine bleach resistance fabric for hospital,work wear – Xiang Kuan , The product will supply to all over the world, such as: Malawi, Macedonia, Tunisia, With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.