Popular Design for 96*48/32/2*16 Plain Water Resistance - 98% cotton 2% 3/1 S twill fire retardant and anti-static fabric 128*60/20A*16A for flame retardant protective clothing – Xiang Kuan

Popular Design for 96*48/32/2*16 Plain Water Resistance - 98% cotton 2% 3/1 S twill fire retardant and anti-static fabric 128*60/20A*16A for flame retardant protective clothing – Xiang Kuan Detail:

| Art No. | MBF9337Z |

| Composition | 98%Cotton2%SA |

| Yarn Count | 20A*16A |

| Density | 128*60 |

| Full Width | 57/58″ |

| Weave | 3/1 S twill |

| Weight | 280g/㎡ |

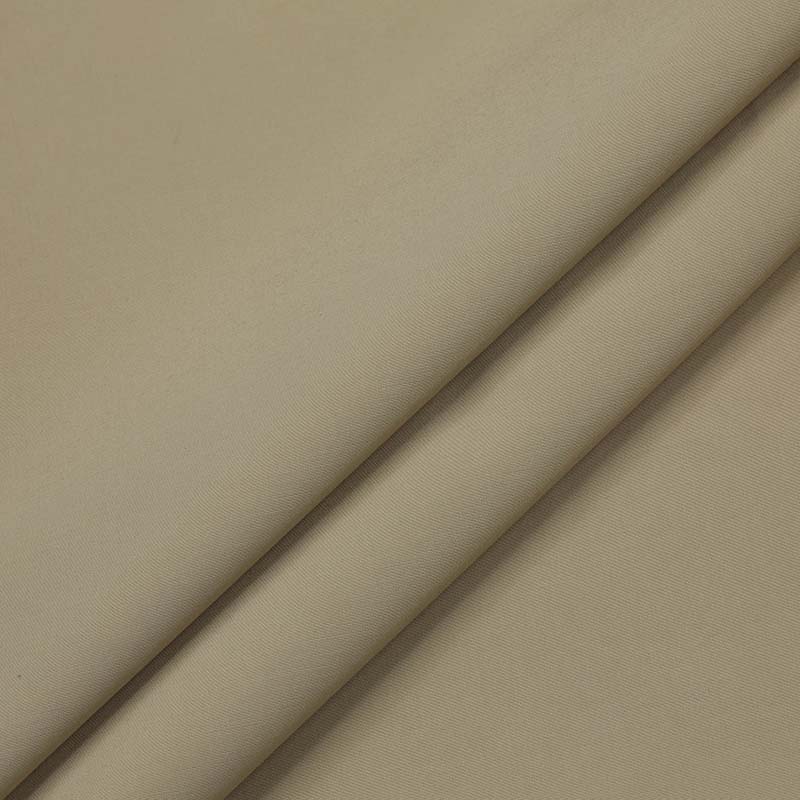

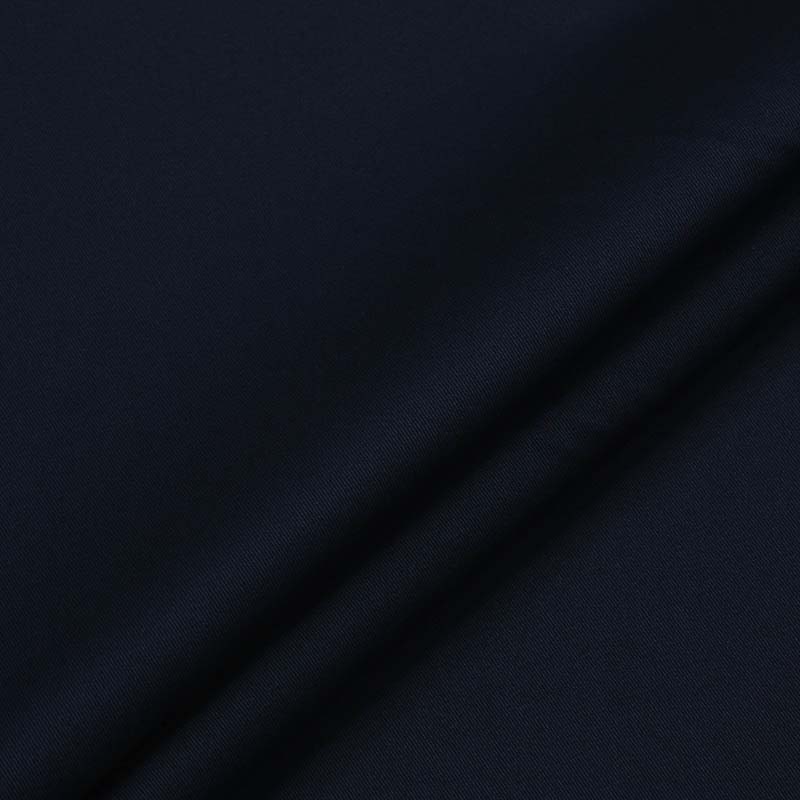

| Available Color | Red, Navy, orange etc. |

| Finish | Flame Retardant, Fire Retardant, Anti-static |

| Width Instruction | Edge-to-edge |

| Density Instruction | Greige Fabric Density |

| Delivery Port | Any port in China |

| Sample Swatches | Available |

| Packing | Rolls, fabrics length less than 30 yards are not acceptable. |

| Min order quantity | 5000 meter per color,5000 meter per order |

| Production Time | 30-35days |

| Supply Ability | 200,000 meters per month |

End Use: Flame retardant protective clothing for metallurgy, machinery, forestry, fire protection and other industries

Payment Terms: T/T in advance, LC at sight.

Shipment Terms: FOB, CRF and CIF, etc.

Fabric Inspection: This fabric can meet GB/T standard, ISO standard, JIS standard, US standard. All the fabrics will be 100 percent inspected before shipment according to American four point system standard.

| Fabric Composition | 98%Cotton 2% SA(10mm lattice conductive wire) | ||

| Weight | 280g/㎡ | ||

| Shrinkage | EN 25077-1994 | Warp | ±3% |

| EN ISO6330-2001 | Weft | ±3% | |

| Color fastness to washing(After 5 washes) | EN ISO 105 C06-1997 | 4 | |

| Color fastness to dry rubbing | EN ISO 105 X12 | 3 | |

| Color fastness to wet rubbing | EN ISO 105 X12 | 2-3 | |

| Tensile strength | ISO 13934-1-1999 | Warp(N) | 1306 |

| Weft(N) | 754 | ||

| Tear strength | ISO 13937-2000 | Warp(N) | 29.8 |

| Weft(N) | 26.5 | ||

| Flame retardant performance index | EN11611;EN11612;EN14116 | ||

| Fabric Composition | 98%Cotton 2% SA(10mm lattice conductive wire) | ||

| Weight | 280g/㎡ | ||

| Shrinkage | EN 25077-1994 | Warp | ±3% |

| EN ISO6330-2001 | Weft | ±3% | |

| Color fastness to washing(After 5 washes) | EN ISO 105 C06-1997 | 4 | |

| Color fastness to dry rubbing | EN ISO 105 X12 | 3 | |

| Color fastness to wet rubbing | EN ISO 105 X12 | 2-3 | |

| Tensile strength | ISO 13934-1-1999 | Warp(N) | 1306 |

| Weft(N) | 754 | ||

| Tear strength | ISO 13937-2000 | Warp(N) | 29.8 |

| Weft(N) | 26.5 | ||

| Flame retardant performance index | EN11611;EN11612;EN14116 | ||

About fire retardant fabric

Among all fire hazards, textiles getting burnt are more due to its widespread use. Majority of fire accidents are associated with the burning of textiles. Cellulosics that is commonly used in garments are comfortable, but are more prone to inflammability. The weight and weave of the fabrics also decides its inflammability. Heavy and tight woven fabrics burn slowly than loosely woven fabrics. Flammability is important, particularly for textiles. A retardant finish is given to fabrics to prevent it from getting burnt.

Product detail pictures:

Related Product Guide:

Fast and fantastic quotations, informed advisers to help you choose the correct products that suits all your needs, a short manufacturing time, responsible good quality control and distinct companies for paying and shipping affairs for Popular Design for 96*48/32/2*16 Plain Water Resistance - 98% cotton 2% 3/1 S twill fire retardant and anti-static fabric 128*60/20A*16A for flame retardant protective clothing – Xiang Kuan , The product will supply to all over the world, such as: Puerto Rico, Algeria, luzern, Our items have national accreditation requirements for qualified, high quality products, affordable value, was welcomed by people today all over the world. Our goods will continue to enhance within the order and look forward to cooperation with you, Should any of these products be of interest to you, please letus know. We are going to be content to offer you a quotation up on receipt of your detailed needs.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!